Intelligent industrial industrial automation

Ronghui Diantong Technology Industrial Automation Control System connects the production site, the edge of the control layer, the cloud people, equipment and management information, providing solutions covering data acquisition, transmission, collection and application, etc. to fully explore the value of enterprise data, shorten production cycle, improve production efficiency and quality, and truly achieve digital, automatic and visual intelligent factory.

Classification

Contact:

Product Details

Smart Industry and Industrial Automation

| Industry users | |||||||

|

Build Paper |

Bag Fit |

Wisdom Hui |

Wisdom Hui |

Metallurgical Gold |

Born things |

Electricity Son |

Shaft Commitment |

| Line | Machine | Electricity | Work | Welding | Medical | Electricity | Plus |

| Industry | Mechanical | Force | Factory | connected | Medicine | Work | Work |

Ronghui Diantong Technology Industrial Automation Control System connects the production site, the edge of the control layer, the cloud people, equipment and management information, providing solutions covering data acquisition, transmission, collection and application, etc. to fully explore the value of enterprise data, shorten production cycle, improve production efficiency and quality, and truly achieve digital, automatic and visual intelligent factory.

Technical advantages

ADVANTAGES

|

Intelligent Industrial Automation System Design can be Customized for you |

|

|

matic operation of equipment Automatio recognition and completion of work instruations, automatio alarm, diagnosis and repair in case of failure. |

jent Decision and Management Connect to cloud big data to realize all-round industrial big data storage, intelligent decision- making, scheduling, planning and management. |

|

Master the working conditions with one hand Remote control, multi-scene fusion, real-time online monitoring. |

Smart ofiice and wlanagementnd Management It provides industrial system integration for manufaoturing enterprises, realizes system integration at different levels from intelligent units, automatic production lines, digital workshops to intelligent factories, and breaks through information islands among various systems of enterprises. |

|

Industrial Internet of Things It provides industrial system integration for manufacturing enterprises, realizes system integration at different levels from intelligent units, automatic production lines, digital workshops to intelligent factories, breaks through information islands among various systems of enterprises, and truly realizes industrial data interconnection and intercommunication. |

Intelligent Service Insight into the explicit and implicit deep needs of customers, comprehensive data analysis, and personalized service. |

Application

APPLICATION

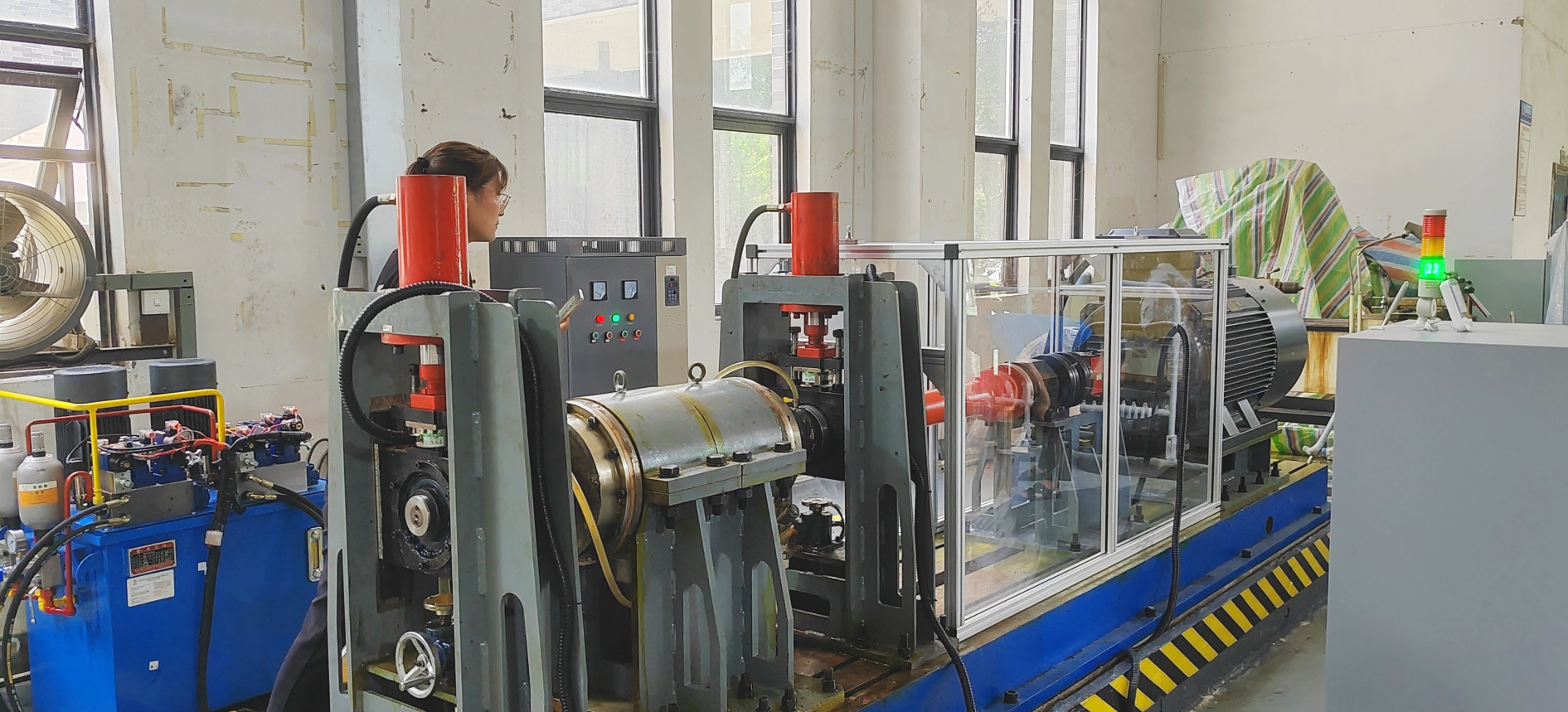

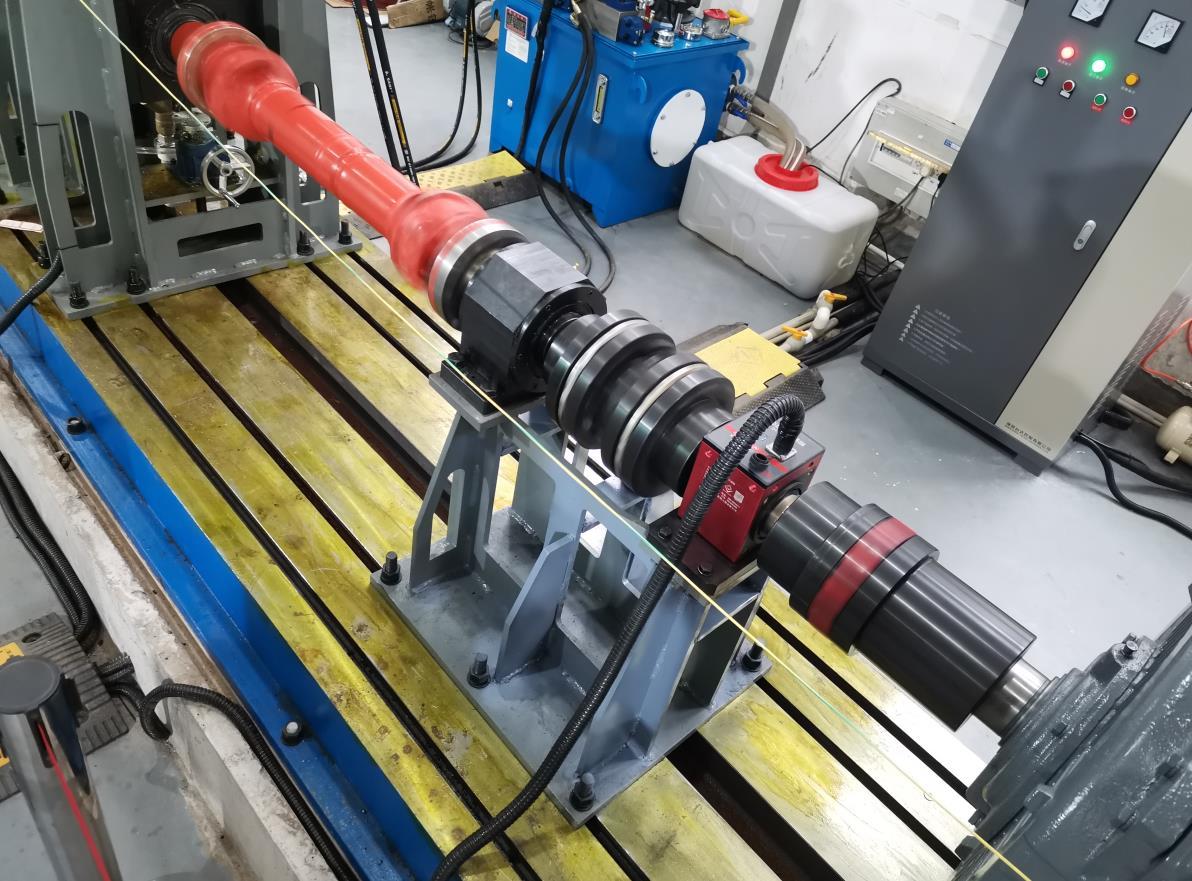

Water lubricated bearing test rig

Water-lubricated bearings are key components of ship propulsion system and must undergo rigorous inspection before leaving the factory. The water-lubricated bearing test rig designed and constructed by the company provides dynamic torque, speed, load, flow, temperature, pressure, displacement and other experimental conditions for it. It runs continuously for 72 hours in seawater environment and successfully passes the acceptance and is delivered for use.

|

|

|

|

Control System of Composite Film Bag Making Machine

The control system of composite film bag making machine is an old product developed more than 20 years ago,and there are two control systems based on industrial PC and PLC (programmable logic controller). It is suitable for bag making machine in the form of three-side seal, middle seal, bottom seal, zipper bag, self-supporting bag, etc. It can be used for processing plastic composite, paper-plastic composite, aluminum-plastic composite, nylon film, non-woven fabric and other materials. Based on the PLC and HMI control system, it can realize multi-axis motion control of servo, stepping and AC asynchronous motors. It can control up to 32 channels of temperature, which has the advantages of easy operation, compact structure, stable and reliable, perfect protection, easy maintenance, etc., and has multiple automatic protection functions as well as superior anti-interference performance.

Cross-cutting machine and die-cutting machine control system

Adopting the new generation of compact programmable controller from Panasonic, it can realize the synchronous work of traction and shearing, and realize the coordinated and stable operation of the whole machine. And it has the power-off data protection function. The use of imported industrial-grade high-grade control components can calmly cope with the complex electromagnetic environment of the industrial site, and the reliability is greatly improved. The linear speed of the system can reach more than 100 meters per minute and the control accuracy can reach 0.1 mm.

Intelligent automatic coating system for power industry

recommend products

Related Products