High Voltage Transmission Line Inspection Robot RH-TF02M4

The High Voltage Transmission Line Inspection Robot RH-TF02M4 can realize live insulation coating on 10kV/35kV/66kV bare wires and automatically go online. The ground remote control system monitors the coating effect in real time online. Manufacturer of wire insulation coating robot -- Ronghui Diantong Technology

Classification

Contact:

Product Details

High Voltage Transmission Line Inspection Robot coating speed: 6 m/min

Apply first gear in 20~30 minutes

High Voltage Transmission Line Inspection Robot

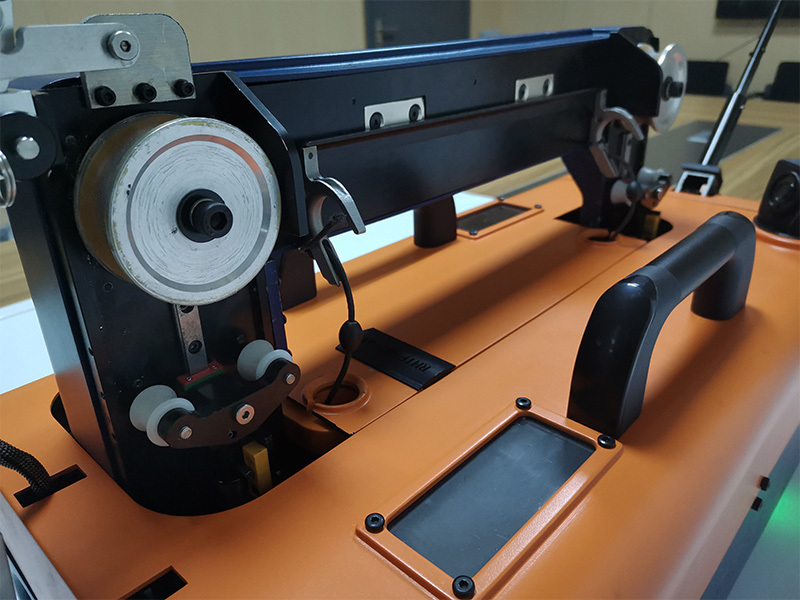

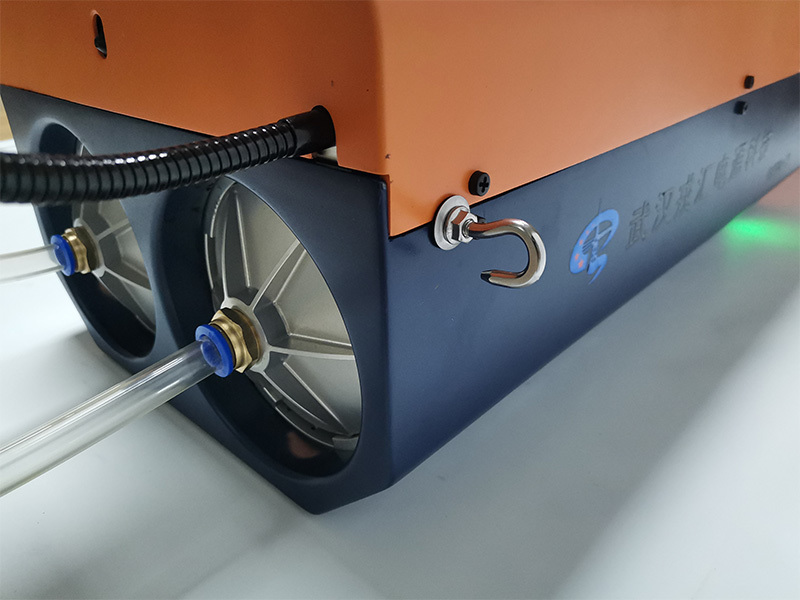

The High Voltage Transmission Line Inspection Robotcan realize live insulation coating on 10kv/35kv/66kv bare wires. The robot and UAV work together to automatically go online. The operation of the coating robot is intelligent and simple, without the need for cooperation of the insulating aerial device and aerial workers. It is applicable to a variety of terrain, especially in the environment where insulating aerial device cannot pass. Autonomous on-line is less restricted by the terrain and the double tank coating operation is highly efficient.

Real shot:

|  |

|  |

High Voltage Transmission Line Inspection Robot

1. Ultralight: RH-TF02M4

Live Work for Insulation Transformation of Overhead Bare Conductor of 10kV/35kV Power Distribution Line

2. Double barrel, high working efficiency, fast speed, high quality coating, uniform thickness and non-eccentric

3. Without the aid of an insulated bucket arm vehicle, use a ground projectile gun (or a throwing unmanned aerial vehicle) to throw the towing rope across the line, hang the hook on the wire, and "automatically go online" with one key ".

4. The robot automatically measures the wire diameter when contacting the wire.

5. Start the "automatic coating" with one key, evenly coat the insulating adhesive on the surface of the bare wire, and the robot will automatically stop when reaching the end of the line to complete the offline process.

6. The robot stops automatically when landing. When the rope is loose, the hook will automatically fall off.

7. The robot can operate without power supply. After the insulation glue is cured, the insulation transformation of the bare wire will be completed.

8. Multi-sensor fusion technology is adopted to realize the intelligent operation of the equipment. Using MIMO wireless communication, it can transmit multiple video signals, control instructions and equipment status parameters at the same time, and monitor the machine status in real time.

Parameters:

Model structure:Double barrels, high working efficiency, high speed, high quality coating, even thickness without eccentricity.

Functional configuration: wire diameter measurement, arc extinguishing device, obstacle ranging, blocking stop, lifting balance,

Multi speed regulation, video 3-way, voice prompt

Applicable wire specification: LGJ50/30 ~ LGJ250/40 (wire diameter: 11.6~22.4)

Equipment size: 1040(L)× 335(W)× 360(H)

Unloaded weight: ≤ 28 Kg

Maximum loading volume: 8L(4 L × 2)

Travel speed: ≤ 10 m/min

Climbing angle: ≤ 30 °

Endurance: ≥ 4 H

Previous article

Previous article

recommend products

Related Products