08

2023

-

06

Independent research and development| Large Capacity and High Efficiency Insulation Coating Robot leaved factory and had a coating test

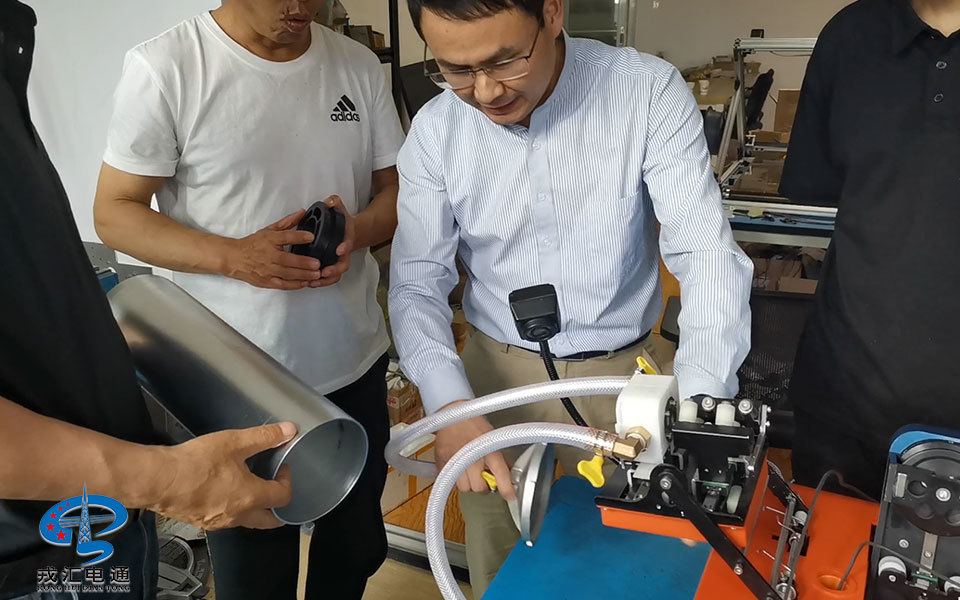

Recently, Wuhan Ronghui Diantong received a number of cooperation on the project of electrified insulation coating robots. In May 2023, our company received a group of new customers to visit again.

Mr. Yang showed customers around and introduced our main products in detail, namely ultra-light insulation coating robot RH-TF01S2 and large-capacity double-bucket insulation coating robot RH-TF01M2. The machine is mainly used in live working of insulation transformation of bare overhead conductor in 10KV/35KV distribution network. The robot adopts a number of patented technologies and applies a variety of advanced new materials and manufacturing processes, so that it can independently up and down the line in the state of no power failure, breaking the traditional situation of manual climbing operations. The operator uses the remote control device on the ground to carry on the wireless remote control, which can transmit the video images and data about the front and rear of the waking line and its own movement state back to the ground, so as to monitor the operation state, inspect the effect of coating and realize the convenient and efficient insulation transformation of the overhead bare wires.

Mr. Yang is introducing some key technologies used by our insulation coating robot to customers: "We are R&D enterprise, mainly focusing on project research in power electronics, intelligent equipment and industrial automation. According to the current market development status quo, there are a large number of enterprises are doing simple solutions, which are not our turn, and we also have no competitiveness. We are currently developing a very complex industrial automation project. Being engaged in independent research and development is our strength, only solving the application problems in the industry is the foundation of our survival."

Key technologies:

1. Dual-channel multi-band anti-interference wireless remote control communication system

The control instruction data volume is small, the transmission bandwidth requirement is low, and the real-time requirement is high; the video image transmission data volume is large, the transmission bandwidth requirement is high, and the real-time requirement is not high. According to the above characteristics, the system adopts dual-channel multi-band transmission technology, which transmits control instructions and video images through independent channels, and each channel adopts two different frequency bands. It effectively solves the contradiction between real-time wireless transmission and transmission bandwidth, reduces the influence of electromagnetic interference and ground objects on communication, and ensures the stability and reliability of remote control operation.

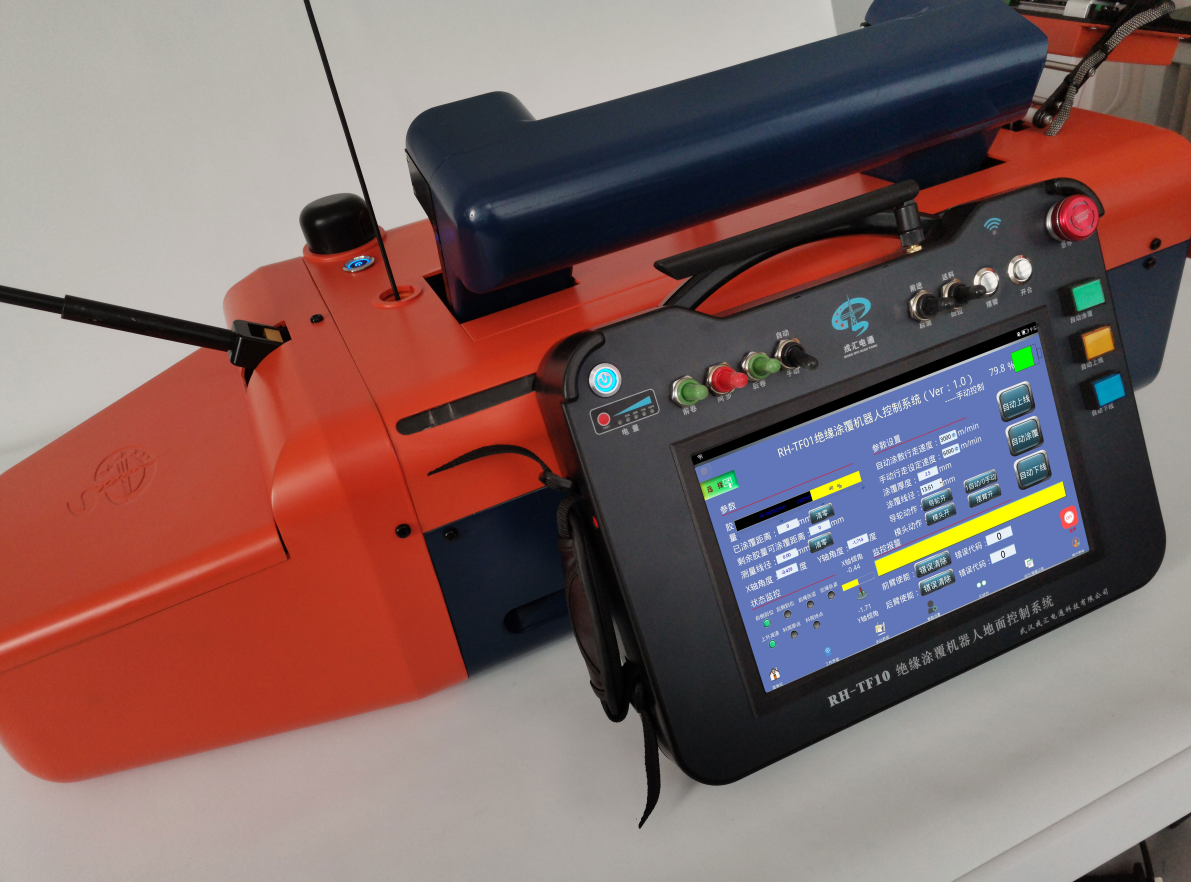

2. Portable cloud remote control

In order to adapt to the diversity and complexity of field applications,the cloud serve, central controller and touch display are seamlessly combined to form an integrated portable handheld remote control, which exceeds the traditional HMI architecture. One handheld control can be connected to three robots at the same time, significantly improving the mobility and convenience of operation.

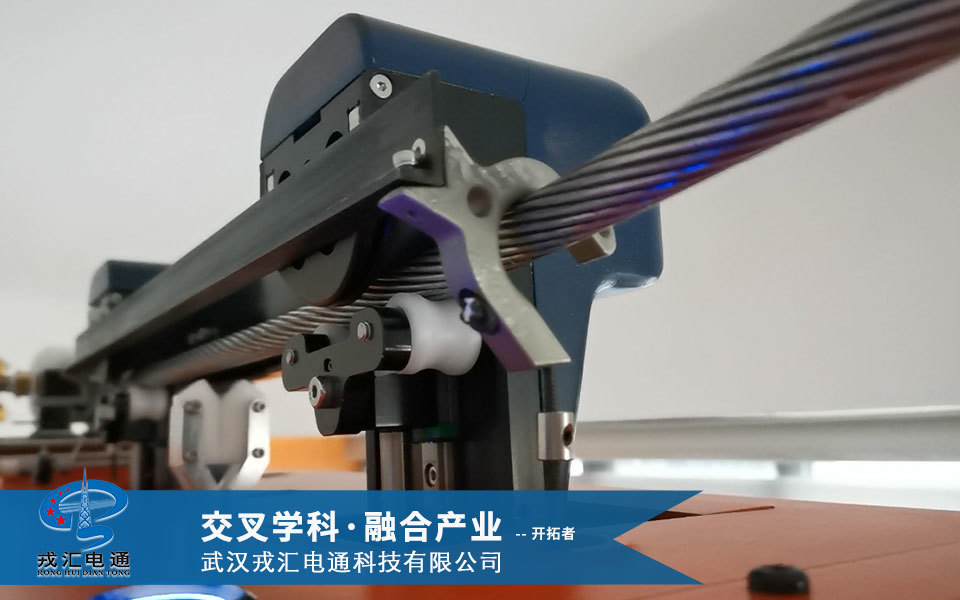

3. Coaxial positioning coating device

Existing power transmission and distribution line coating devices generally use grooved wheels to guide conductors. Because the size of the grooved wheel is fixed, the applicable wire diameter range is small; the angle between the wire and the horizontal direction is not fixed, and the force on the grooved wheel is uneven. The device effectively solves the problems of eccentric coating layer, small adaptive wire diameter range, uneven stress of positioning and pressing parts and the like of the existing power transmission and distribution line groove wheel positioning and coating device.

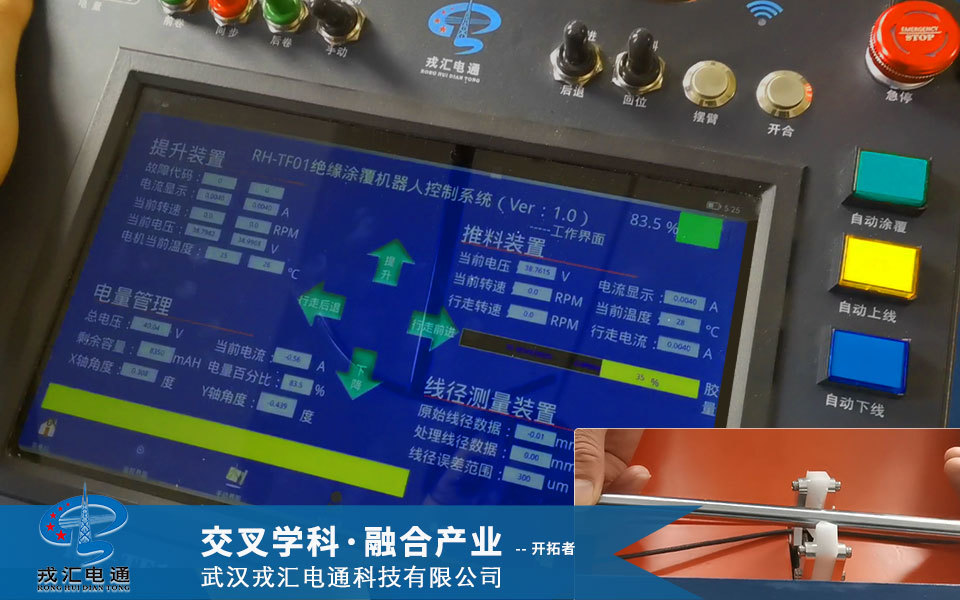

4. Wire diameter measuring device

To accurately calculate the coating thickness, traveling speed, glue injection flow and other parameters according to mathematical models, the insulation coating robot must be based on accurate line diameter values. If the set line diameter values differ greatly from the actual line diameter, it cannot meet the coating thickness, concentricity, surface smoothness and other process requirements. The wire diameter measuring device is equipped with the function of all series robots, which can accurately measure the wire diameter when the equipment is online. If the error between the measured value and the system setting value is large, the operator will be prompted to change the setting value, change the glue outlet and other subsequent treatments to ensure the coating quality.

5, Integrated multi-axis CNC system

Lifting, walking, injection of multiple motors are driven by integrated digital servo system, using torque compensation algorithm based on current mutual inductance, small size, light weight, high precision, easy to integrate control.

6. Balance lifting system

The robot adopts double-rope lifting dynamic balance algorithm to realize pitch balance in the process of robot up and down line, and provides stable posture for robot up and down line stably and swing arm hanging line.

7. Self-adaptive gradient walking wheel compression device

The compaction force of the compaction wheel is composed of an electric cylinder transmission mechanism, and the compaction force is adjusted in real time through the sampling data of the inclination sensor and the pressure sensor, so that the self-adaptive closed-loop control of the compaction force and the walking slope of the robot is realized, and the uphill and downhill ability of the robot is improved, and the energy consumption is saved.

8, Application of various functional materials

The traveling wheel is made of polyurethane elastic wear-resistant material wrapped by aluminum alloy wheel hub, and the compression and guide device is processed by polyformaldehyde material with high hardness and low friction coefficient, which not only ensures the driving force of traveling, but also greatly reduces the friction resistance of the driven wheel to prevent damage to the transmission line.

In the morning, our company demonstrated the automatic on-off and off-line operation of the entire insulation coating robot and the insulation coating test for customers. The whole process was successfully completed. The customer evaluated that our company's insulation coating robot has great advantages in independent research and development in terms of the market, and it was upgraded and transformed in the later stage. It is very fast and convenient, and many functional designs really fit the actual situation on site, take care, and are very practical. The weight is also very light on the market, which is very suitable for insulation transformation of small wire diameter or old lines. Overall, it is a charged insulation coating robot that fits the market and site conditions and has a high cost performance.

In the afternoon of the same day, the customer reached cooperation with our company, RH-TF01M2 medium-sized large-capacity insulation coating robot was sent to the customer site the next morning.

05

/

20

Related News

12

/

06

Related News