25

2023

-

04

It's magic! Charged insulation coating "magic weapon" to understand

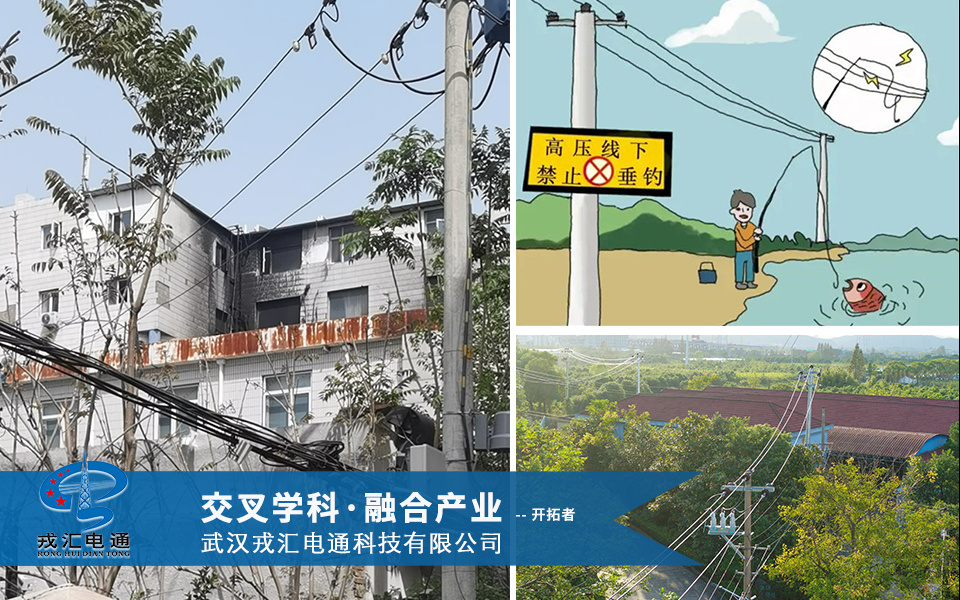

As an important part of the power grid, the distribution network is directly oriented to end users, and its safety and reliability are closely related to people's life. The 10kV and 35kV overhead conductors crisscross and numerous, spread throughout the urban and rural areas, fields and mountainous areas. It often affected by overgrowth of trees, wind dancing, bad weather and other external damage, and there are often situations that the safety distance is not enough, illegal construction and fishing under the line, resulting in frequent line tripping and power outage resulting in stoppage of work and production. This can cause serious casualties, forest fires and other major accidents in severe case.

How to ensure the power supply reliability of overhead lines in the distribution network and eliminate the insulation hidden danger is an urgent need related to the power supply safety of urban and rural power grids.

At present, there are two traditional reconstruction construction schemes, the first one is to directly replace the new insulated conductors; the second one is to change overhead to buried. Although both can solve the problem, replacing bare conductors is a large project, which takes a long time, costs a lot, and is difficult to construct; and power outage is required for construction.

Replacing Insulated Conductor with Power Failure

Or digging trenches and laying lines.

In response to this pain point, security operation and maintenance urgently needs a new way to make up for the shortcomings of traditional methods.

Ronghui Diantong's RH-TF01S2 live insulation coating robot for overhead bare conductors has developed an ultra-light self-online insulation coating robot after long-term exploration, continuous optimization and upgrading, which does not require workers to climb. It can work without power failure, and put a layer of "leather jacket" on bare wires at a speed of 3-8 meters per minute. After curing of the insulation adhesive for 24 hours, the insulation transformation of bare wires is completed.

21kg Light weight, suitable for LGJ25/4 and above bare conductors

Only need operation and maintenance personnel operate remotely on the ground.

Light and efficient, especially suitable for insulation transformation of small diameter or old lines.

One machine in hand, HD(high-definition) image, video storage, wonderful presentation.

The remote controller adopts dual-channel multi-band wireless communication system

MIMO wireless communication, which simultaneous transmission of multi-channel video signals, status parameters, control instructions, realizes the intelligent operation of equipment

Multi-path adaptation

Multi-caliber turntable for easy adjustment of adhesive outlet caliber

Adapt to wires of various specifications.

Automatically measure wire diameter

automatic correction of parameters

Easy to operate, safe and efficient

One-click completion of "Automatic online", "automatic coating" and "automatic offline".

Automatic landing stop, automatic decoupling.

05

/

20

Related News

12

/

06

Related News