Overhead Bare Wire Insulation Transformation Solution

Classification:

Smart Power

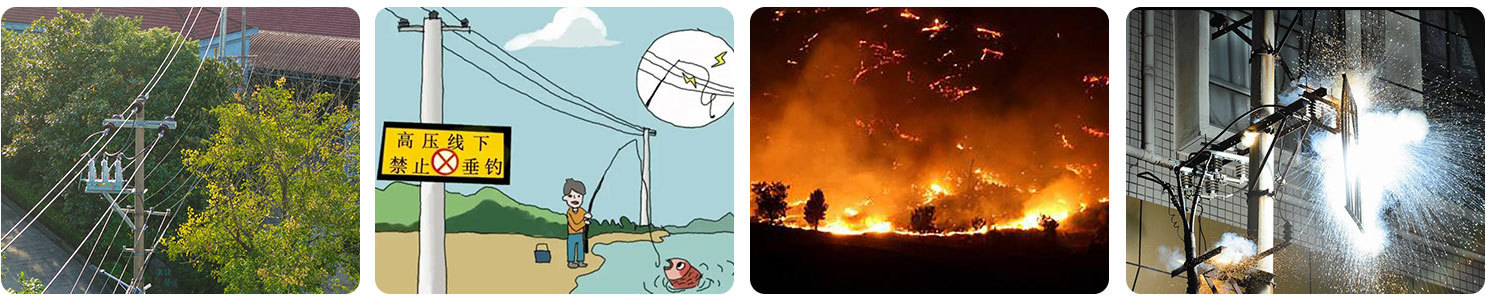

There are a large number of overhead bare conductors in power grid distribution lines, which often pass through woods, waters, high-rise buildings and densely populated areas, and are prone to accidents such as personal accidental electric shock, bird's nest grounding trip, and tree short circuit fire.

With the rapid development of urbanization in China, such accidents occur frequently, which seriously affect the safe operation of power grid and pose a great threat to the safety of people's lives and property.

Short circuit of fishing trees under the bare wire crossing the high-voltage line in the area with dense trees causes insufficient distance of the line of the mountain fire house.

At present, the insulation rate of distribution network is about 29%. There are two main methods for safety transformation of existing overhead bare wires: replacing insulated wires and overhead insulation.

| Replace insulated conductor/buried | Insulation coating | |||

|---|---|---|---|---|

| Live working | Power outage | |

Live working | Charged |

| Security risk | High | Security risk | Low | |

| Green compensation for land acquisition | Need | Green compensation for land acquisition | No need | |

| Construction time | Long | Construction time | Short | |

| Cost | High | Cost | Low | |

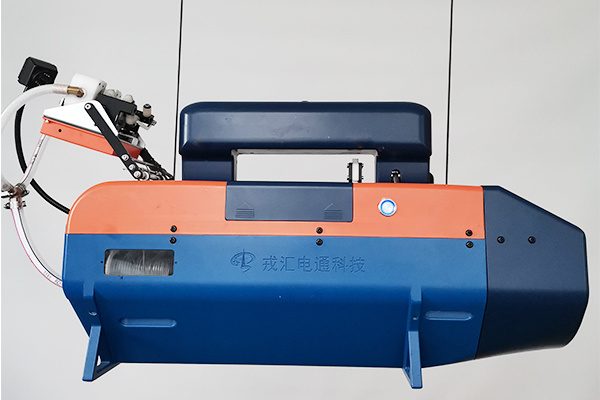

10KV/35KV

Autonomous on-off and off-line power-up operation 30min table dry

12h full dry

No need to use insulated bucket arm car

high quality coating, uniform thickness without eccentricity

-

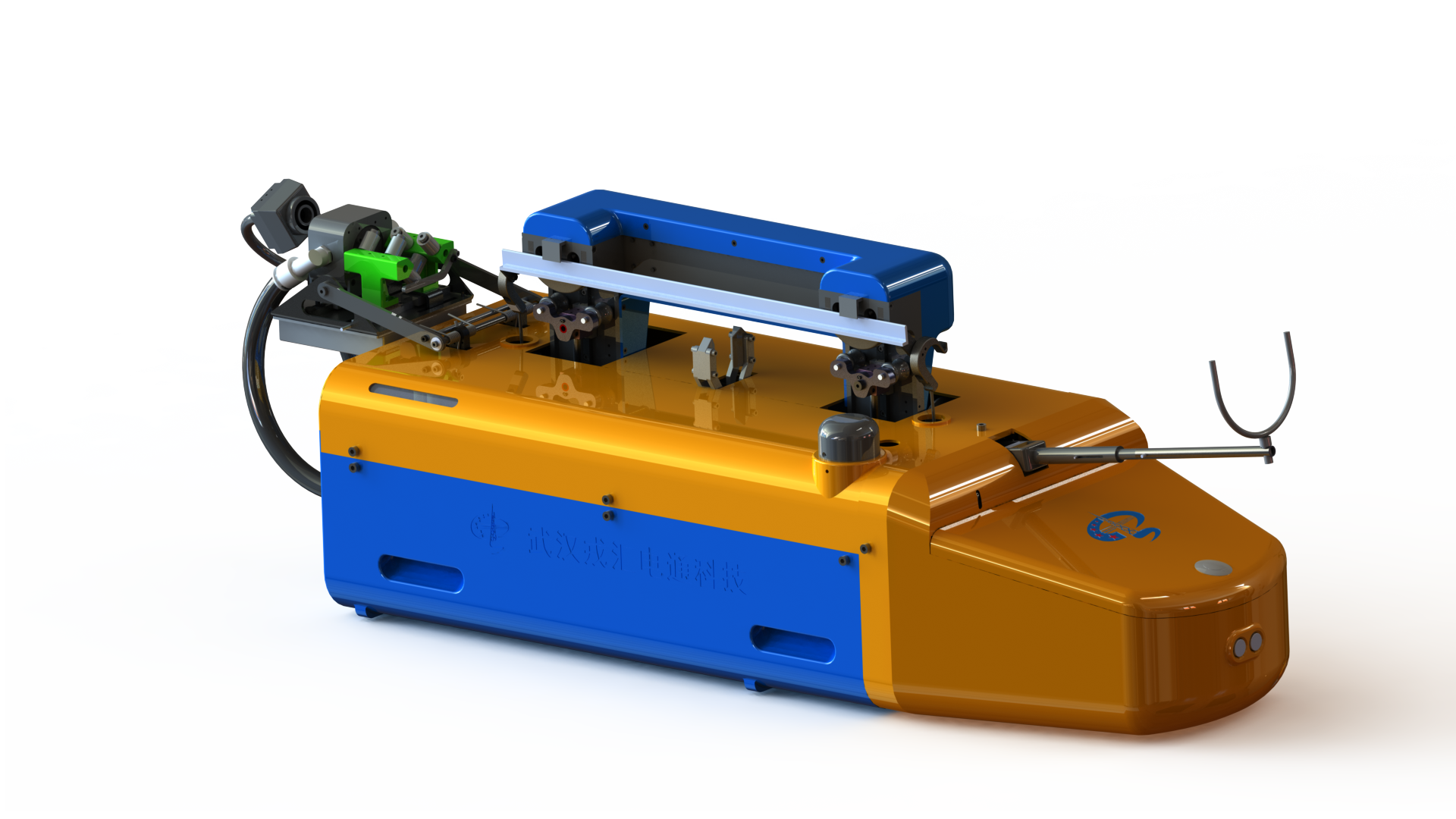

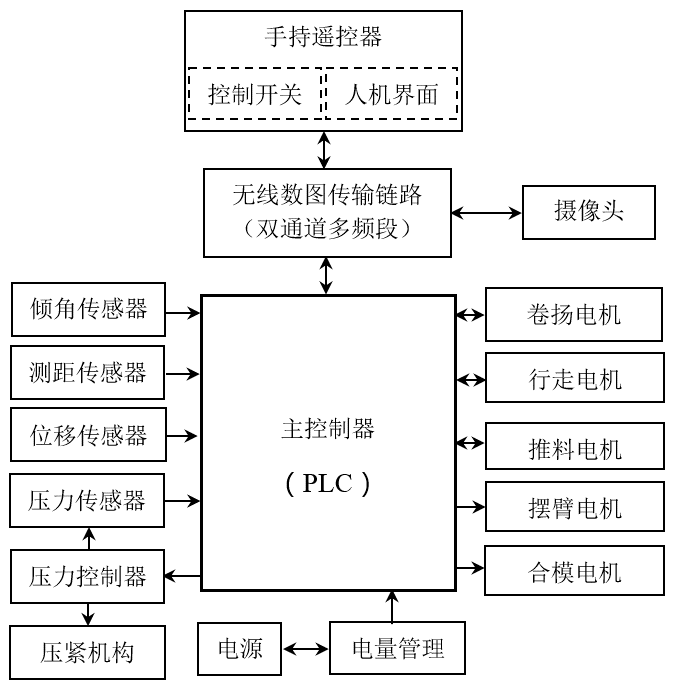

Dual-channel multi-band anti-interference wireless remote control communication system

▷ Instruction and video image independent transmission, real-time display

▷ Anti-interference, remote control operation, stable and reliable

- Synchronous alignment coaxial guide device

Two-sided synchronization, multi-wire diameter adaptation, uniform coating.

- Balanced lifting system

▷ Dynamic balancing algorithm

▷ Up and down line, swing arm hanging line, pitch balance and stable attitude

-

Portable cloud remote control

Adapt to harsh and complex environments

▷ Can achieve one drag three

-

Slope adaptive pressing device (medium | large)

▷ Realize pressing force, walking slope adaptive

▷ Improve the robot's ability to go up and down slopes, saving energy consumption

- Integrated multi-axis numerical control system

The digital servo system is adopted for lifting * 2, walking and glue injection.

▷ Small size, light weight, high precision, easy control

19947665119

Answer Line Contact Us

Next page:

Related Cases